Disadvantages Of Laser Cutting

Laser cutting involves the application of high-power density laser energy. The CNC controller turns on the laser generator, which produces a high-frequency laser pulsed in a continuous manner. This creates a beam having a specified frequency and pulse width. The beam is transmitted and refracted through the optical pathway and focused by an focusing lens group. A tiny, high intensity, light spot is formed on the part's surfaces. The focal points are located near the surface that will be cut. The material melts or evaporates at an immediate high temperature. Each laser pulse will create a small hole in your substrate. The computer numerical control allows the laser head to move and dot in continuous relative to the substrate according to the specified file. This allows for the substrate to be cut to the desired shape.

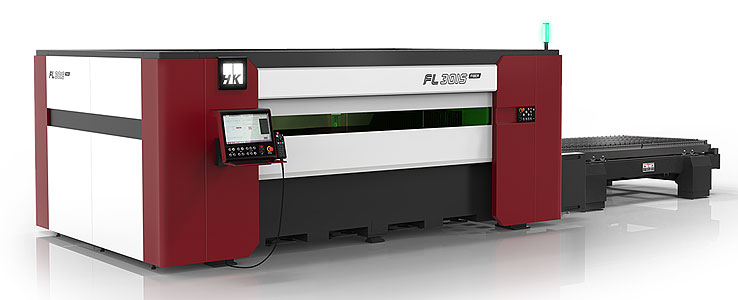

Fiber laser was introduced in the market in circa 2008. Fiber lasers possess a higher speed of cutting and low operating costs. At the beginning of this invention, it couldn�t perform on thicker metals.